Robotics & AI in Electronics Manufacturing: Efficiency Meets Skilled Workforce Security

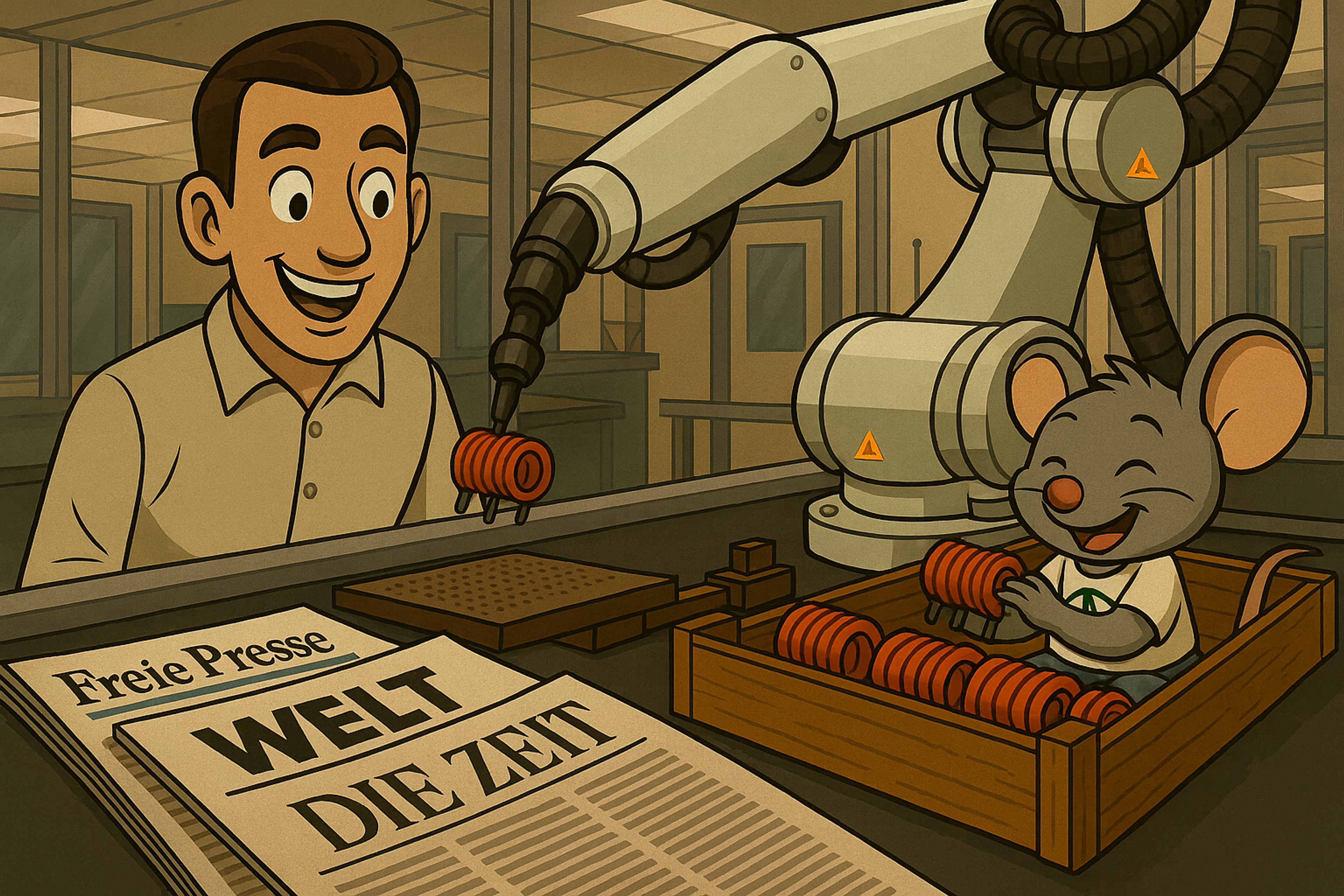

How Arnold Electronic designs future-proof production – featured in ZEIT, Freie Presse, and WELT

Electronics manufacturing is changing – not at some point in the future, but now. Three major publications – DIE ZEIT, Freie Presse, and WELT – are currently reporting on Arnold Electronic GmbH and our approach to key challenges: automation, skilled labor shortages, and innovation pressure.

Our answer: Technology with a sense of proportion

With the new tinning robot 'Robby', we have taken a clear step towards intelligent automation – not as a replacement for humans, but as support. Especially in areas where there is a shortage of skilled workers, Robby takes over monotonous, yet precise tasks in the manufacturing of inductive components.

This is what the media say:

- 📰 DIE ZEIT: "Robots and AI in Small and Medium-sized Enterprises"

- 🗞️ Freie Presse: Digitalization & Employee Retention in Harmony

- 🗞️ WELT: SMEs as an innovation driver

What drives us:

- Customized electronic solutions – not mass production, but client-specific projects

- Stability in change – through digitalization with responsibility

- Strong partnerships – e.g., with ICM Chemnitz and the Sächsischen Aufbaubank (SAB)

Our guiding principle remains:

📍 The human being remains central – technology should relieve, not replace.

👉 Learn more about our solutions in electronics manufacturing now.

View projects

📣 Join the discussion with us on LinkedIn:

How do you handle the balancing act between automation and securing skilled labor?