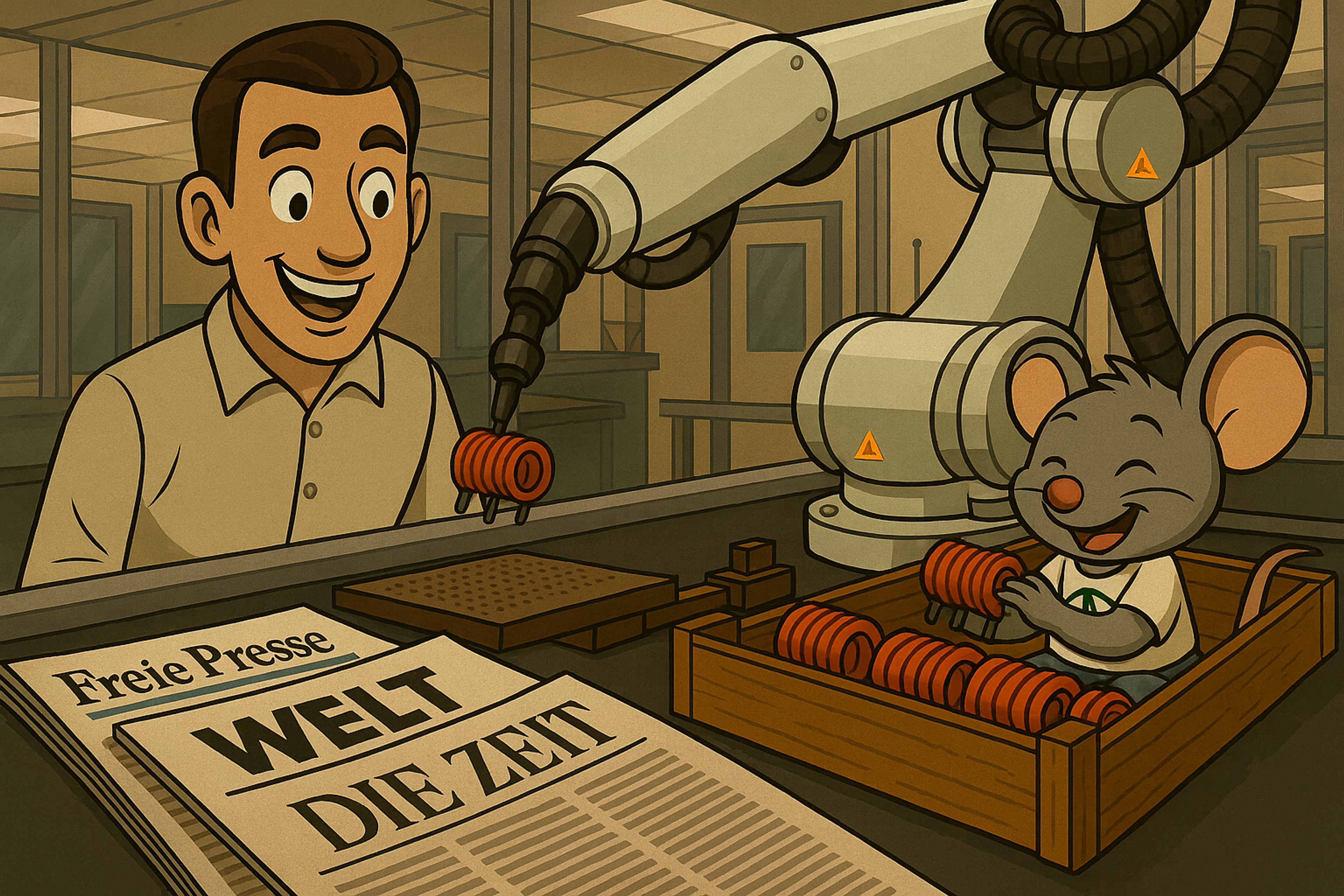

From prototype to production: Efficiency through in-house manufacturing

Short distances, clear processes – custom electronics solutions from a single source

At Arnold Electronic, no solution is 'off the shelf' – each product is based on a real customer project. But what happens between the idea and mass production? Our key to success lies in the depth of manufacturing: from the first sketch to the tested assembly, everything remains in-house.

An overview of our strengths:

- Prototype development with direct access to manufacturing

Development and production work side by side. This saves time, reduces coordination effort, and enables rapid modifications. - In-house expertise in cable assembly and coil construction

We manufacture ourselves – flexible, documented, tested. Variants or short-term adjustments can be implemented at any time. - Integrated Quality Assurance

From pilot production to serial manufacturing, every batch remains traceable. Test protocols, serial numbers, and documented processes ensure long-term reliability.

Why this matters to you:

In-house manufacturing means control, speed, and implementation expertise – especially for complex requirements, small quantities, or sensitive development projects.

👉 Learn more about our manufacturing process now – or discuss your project with us here directly.